Welcome to our website!

TEL: +86-769-88894418 中文简体 | ENGLISH

MAIN BUSINESS

All categories

Aluminum alloy template

- Categories:Main Business

- Time of issue:2021-04-25 14:29:11

- Views:0

Description:

Information

In 2016, the company established the Aluminum Alloy Formwork Division, the new site is located in Sanchong Village, Zhongtang Town, Dongguan City, covering an area of 30,000 square meters. The company's main business is research and development, design, production, sales, leasing, contracting and construction of aluminum alloy formwork and building civil construction systems, with an annual production capacity of 150,000 square meters. Customers are located in the Pearl River Delta region and have established good partnerships with large domestic real estate companies such as Vanke, Evergrande Real Estate, Times Real Estate, and Hongyu Real Estate.

The company has independently developed and effectively applied an advanced sheet metal formwork system. It has a professional aluminum mold construction guidance team and industry-leading old board renovation capabilities to provide customers with a full range of services.

2: Advantages of pull-sheet aluminum alloy template

1. Short construction period

Early dismantling system design, one set of formwork, three sets of supports, 4-6 days per bid section, can be streamlined construction, improve construction progress, and save management costs.

2. Wide range of applications

It is suitable for the use of walls, horizontal floors, columns, beams, stairs, windowsills, floating boards, toilets, etc. It is also useful for secondary structural support such as ring beams, structural columns, and anti-sills.

3. Good stability

The bearing capacity of the aluminum formwork can reach 60KN/m ², which can meet the supporting bearing capacity requirements of most residential, industrial construction, pipe gallery, basement and other projects.

4. High construction efficiency

Standardized design, easy to assemble, the standard board is about 22kg/m², manual mixing, handling and assembly, no mechanical assistance, up to 50 m² person/day, saving cost.

5. High reuse rate

Using integrally extruded aluminum alloy profiles as raw materials, the standardized construction can be reused more than 150 times, and the average cost is low.

6. Good demoulding effect

There are few joints, high precision, and the surface quality of concrete is smooth and clean, which can meet the requirements of finishes and fair-faced concrete. There is no need for batching, which can save batching costs.

7. Civilized construction

The accessories can be reused, there is almost no garbage on site after demoulding, the support system is simple in structure, easy to dismantle, and the whole construction environment is safe, clean and tidy.

8. Low carbon, energy saving and emission reduction

All materials are renewable materials, which meet the national policy requirements for energy conservation, environmental protection, low carbon, and emission reduction in construction projects.

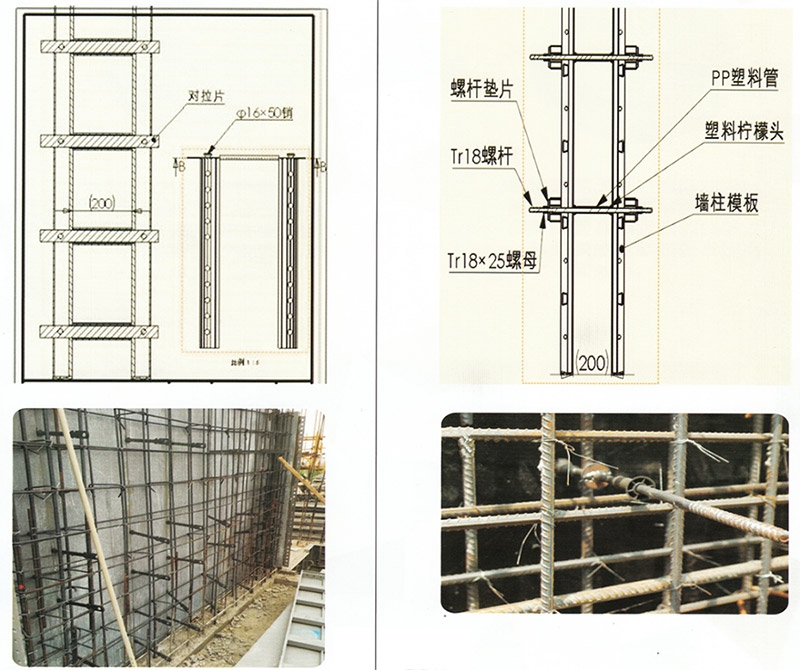

9. Comparison of pull-tab type and screw type

9.1 Screw system of other companies

For special node locations (T-shaped walls, large wall lengths, wall stacks, etc.), when the back flute needs to be added, the template needs to be opened.

When the wall is long, it cannot be installed in a misplaced position, and a long whole backing is required, which is not easy to install, too clumsy, and difficult to reinforce.

Need to install plastic casing, plastic cup, wall screw, gasket, nut, etc., the process is cumbersome, reducing efficiency, the wall hole (not less than 16mm) must be filled, and the outer wall needs to be drained, which increases the process and cost.

9.2 Yixin pull film system

The position of special nodes (T-shaped wall, longer light body length, wall stacking, etc.) can be added at any time without other process processing on the template, which is convenient and quick.

When the wall is long, it can be installed in a staggered way to ensure that there will be no mold expansion.

The use of disposable pull tabs eliminates the need to install plastic sheaths and pull tabs, shortens the installation time, does not need to fill gaps, and does not need to be drained on the outer wall (the fracture is 5.7mm from the wall), which reduces the process and saves the overall cost.

3: Photos of the company's environmental products

1. Office building of Aluminum Formwork Division

2. Aluminum alloy template production workshop

3. Sample room

ABOUT US

PRODUCTS

ADD: Fengchong Village Industrial Zone, Zhongtang Town, Dongguan City, Guangdong Province

TEL: +86-769-88894418

FAX: +86-769-88894418

E-MAIL: sino@gdyixin.net

COPYRIGHT © 2021 Dongguan Yixin Qingjiang Machinery Manufacturing Co., Ltd. All rights reserved. 粤ICP备10047695号

COPYRIGHT © 2021 Dongguan Yixin Qingjiang Machinery Manufacturing Co., Ltd.